muraayadda 8k 304 316 xaashi bir ah

Sharaxaad Gaaban:

Qalab : 304 316 304L 316l 3 309s 310s 321

Farsamada: Kulul duuban / qabow duuban

Dusha sare:Muraayad 8K

Heerka Alaabta

| No.1 | GB | ruushka | AISI, A STM | JIS | BS | DIN | ISO |

| 1 | 1Cr18Ni9 | 12KH18H9 | 302, S30200 | SUS302 | 302S25 | X12CrNi88 | 12 |

| 2 | 0Cr18Ni9 | 08KH18H10 | 304, S30400, TP304 | SUS304 | 304S15 | X5CrNi89 | 11 |

| 3 | 00Cr19Ni10 | Z2CN18.09 | 304L S30403, TP304L | SUS304L | 304S12 | X2CrNi189 | 10 |

| 4 | 1Cr18Ni9Ti | X10CrNiTi189 | |||||

| 7 | 0-1Cr18Ni12Mo2 Ti | Z6CNDT17.12 | 320S17 | X10CrNiMoTi1810 | |||

| 8 | 00Cr17Ni14Mo2 | 03KH17H14M2 | 316Ls S31603, TP316L | SUS316L | 316S12 | X2Cr | 19,19 |

| 9 | 0Cr25Ni20 | 310S, S31008s TP310S | SUS310S | ||||

| 15 | 0Cr23Ni13 | 309S, S30908 | SUS309S | ||||

| 16 | 0Cr17Ni12Mo2N | 316Ns S31651 | SUS316N | ||||

| 17 | 00Cr17Ni13Mo2N | Z2CND7.12N | SUS316LN | X2CrNiMoN1812 | |||

| 18 | 0Cr18Ni12Mo2Cu | SUS316JI | |||||

| 19 | 00Cr18Ni14Mo2Cu2 | SUS316JIL | |||||

| 20 | 0CM9NM9N | ZCNS18.09A2 | 304 | SUS304N |

Qayb Kiimiko ah

| Darajo | C | Cr | Ni | Mo | Mid kale |

| 301 | ≤0.15 | 16.0-18.0 | 6.00 ilaa 8.00 | - | - |

| 301L | ≤0.030 | 16.0-18.0 | 6.00 ilaa 8.00 | - | N≤0.20 |

| 304 | ≤0.08 | 18.0-20.0 | 8.00-10.50 | - | - |

| 304J1 | 0.02 ilaa 0.05 | 16.5 ilaa 17.1 | 7.5-7.9 | - | Cu1.9~2.2 |

| 304L | ≤0.030 | 18.0-20.0 | 9.00-13.00 | - | - |

| 304N1 | ≤0.08 | 18.0-20.0 | 7.00 ilaa 10.50 | - | N0.10~ 0.25 |

| 304N2 | ≤0.08 | 18.0-20.0 | 7.50 ilaa 10.50 | - | Nb≤0.15 |

| 316 | ≤0.08 | 16.0-18.0 | 10.00 ilaa 14.00 | 2.00 ilaa 3.00 | - |

| 316L | ≤0.03 | 16.0-18.0 | 12.00 - 15.00 | - | - |

| 321 | ≤0.08 | 17.0-19.0 | 9.00-13.00 | - | Ti5×C% |

| 409L | ≤0.03 | 17.0-19.0 | - | - | Ti6×C%~0.75 |

| 410L | ≤0.03 | 11.0-13.5 | - | - | - |

| 430 | ≤0.12 | 16.0-18.0 | - | - | - |

| 430J1L | ≤0.025 | 16.0-20.0 | - | - | Nb8 (C%+N%) 0.8 Cu0.30~0.80 |

| 436L | ≤0.025 | 16.0-19.0 | - | 0.75 ilaa 1.25 | Ti, Nb, Zr8 × (C%+N%)~0.8 |

| 410 | ≤0.15 | 11.5 ilaa 13.5 | - | - | - |

| 420J1 | 0.16 ilaa 0.25 | 12.0-14.0 | - | - | - |

| 420J2 | 0.26 ilaa 0.4 | 12.0-14.0 | - | - | - |

| 2205 | 0.38 ilaa 0.43 | 21 ilaa 23 | 4.5 ilaa 6.5 | 2.5 ilaa 3.5 | - |

| 2507 | ≤0.03 | 24.0-26.0 | 6.00 ilaa 8.00 | 3.0-5.0 | - |

Dusha Hordhac

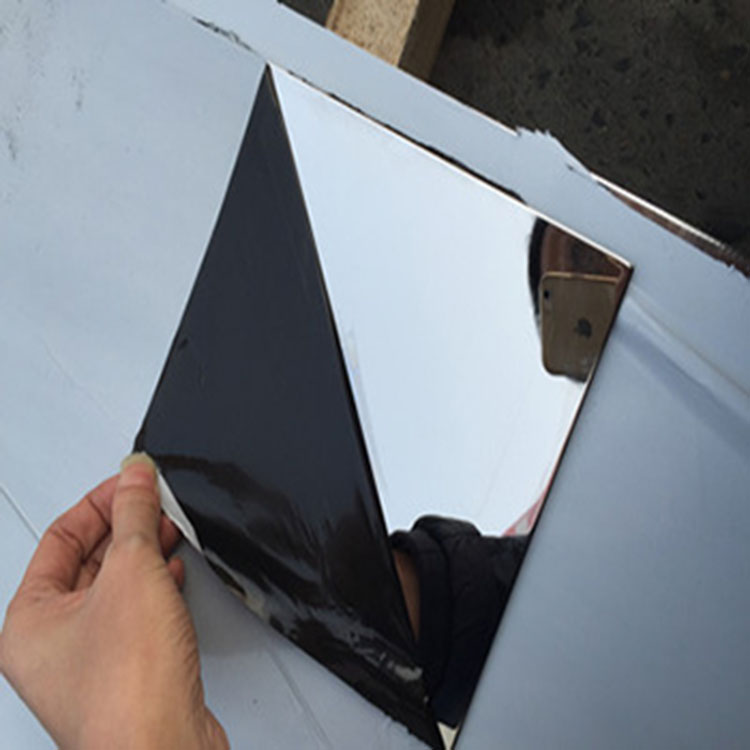

8K DHAMEYSO:

Ku nadiifinta saxanka birta ah ee aan lahayn dareere dhalaalaysa iyadoo la adeegsanayo qalabaynta, si iftiinka saxanku u cad yahay sida muraayadda oo kale.

Sharaxaad: Qalabka ceeriin ee birta ah, ka dib shiidi iyo polishing processing, oogada waxay noqon doontaa siman oo leh dhaldhalaalka muraayadda, saxan bir ahama,

halkaaswaa 2B, BA, oogada caadiga ah, oogada 8K, oogada 8K ayaa ugu fiican.8kxaashi bir ahwaxaa lagu dhejin karaa midab, sida saxan midabka birta ah ee 8k

Codsiga

waxaa loo isticmaalaa looxa gidaarka hoolka, saqafka, looxa gaariga wiishka, guddiga baabuurta, qurxinta dhismaha, calaamadaha iyo qurxinta kale, looxa ahama midabka midabka guud ahaan loo isticmaalaa in qurxinta derbiga iyo qurxinta kale.

Bandhiga Alaabta

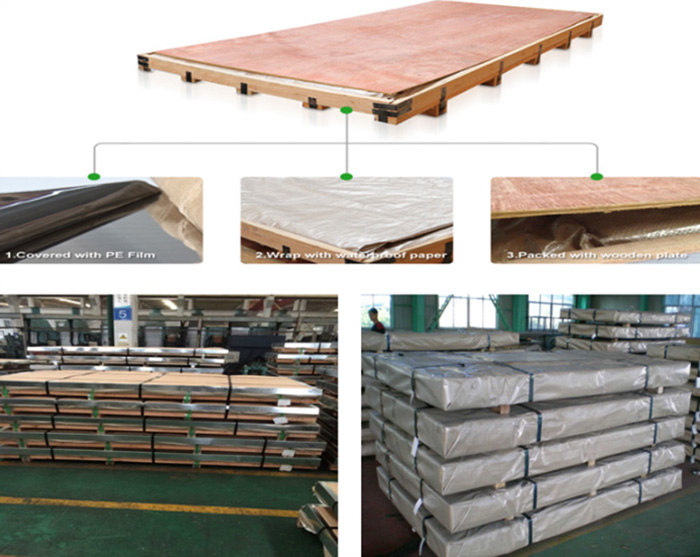

Xidhmada