A few days ago, a major Sino-Russian energy cooperation project, the Yamal LNG project, was officially put into operation. Behind this super project known as “the energy pearl embedded in the Arctic Circle”, TISCO once again demonstrated its stainless strength. More than 10,000 tons of special stainless steel materials provided strong support for the construction of the Yamal project.

The Yamal LNG project is my country’s first overseas super-large project to promote the construction and implementation of the “Belt and Road”. It is jointly developed by Russia’s Novatek, China National Petroleum Corporation, France’s Total and China’s Silk Road Fund. After the project is completed, it can produce 16.5 million tons of liquefied natural gas and 1 million tons of condensate every year. As the first full-industry-chain cooperation project between China and Russia in the Arctic Circle, the Yamal project has become an important fulcrum of the “Ice Silk Road”, which can not only drive the development of Russia’s energy industry and border areas, but also enrich my country’s clean energy supply. Accelerate the optimization of my country’s energy structure.

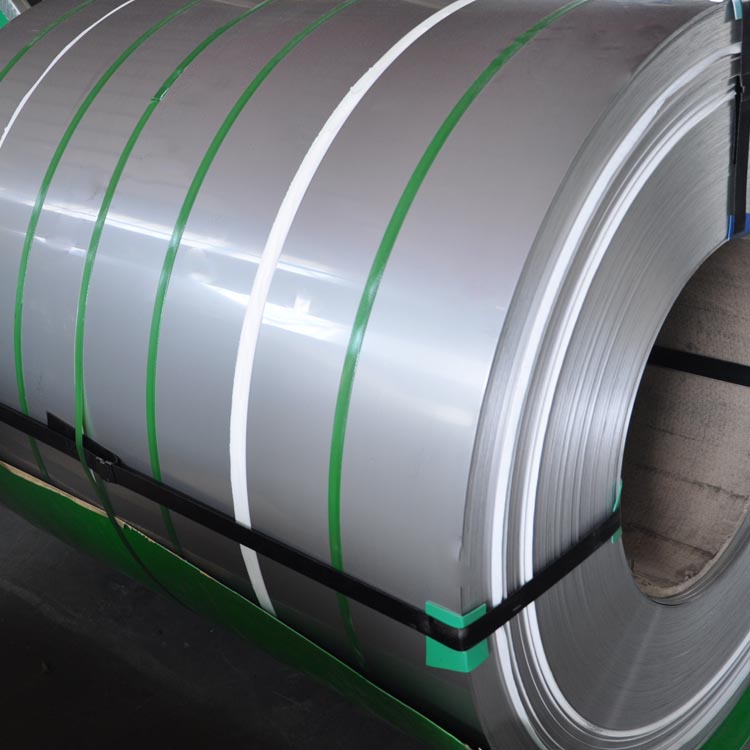

The Yamal LNG project is located in the port of Sabetta on the Yamal Peninsula in the Nenets Autonomous Region of Russia in the Arctic Circle. In the Nenets language, Yamal means “end of the world”. Although the area is rich in natural gas resources, shallowly buried and clean, the natural conditions are harsh and the lowest temperature can reach minus 52°C. LNG projects require the use of a large number of high-quality stainless steel pipes, and the low temperature puts forward higher requirements on the resistance of related materials. In 2014, after fully understanding the project needs, TISCO actively cooperated with well-known domestic direct management enterprises and successfully entered the list of qualified suppliers for the Yamal project. Afterwards, we tackled key technical problems such as low-temperature embrittlement and low-temperature welding of stainless steel materials in extremely cold climates. After repeated tests, we successfully developed special stainless steel pipes with high corrosion resistance, good low-temperature impact toughness and excellent welding performance. The technological requirements of stable performance and easy construction under conditions. Up to now, TISCO has supplied more than 13,000 tons of special stainless steel materials to the Yamal project, with a pipeline length of more than 60 kilometers, which has strongly supported the construction of the Yamal project.

As a leading enterprise in the stainless steel industry, TISCO adheres to the drive of innovation, and has always been committed to the R&D and production of key materials. Upgrading. In recent years, TISCO has taken advantage of the great historical opportunity of “going out” of national high-end equipment, aimed at high-end demand, actively linked with upstream and downstream enterprises and scientific research institutes, and successively developed a batch of high-speed rail, nuclear power, shipbuilding, petrochemical and other industries. The key materials, TISCO products have won high recognition from customers and effectively enhanced the competitiveness of enterprises, but also made positive contributions to the overall improvement and sustainable development of my country’s stainless steel industry.

Post time: Feb-16-2022