drych 8k 304 316 taflen ddur di-staen

Disgrifiad Byr:

Gradd Deunydd:304 316 304L 316l 3 309s 310s 321

Techneg: rholio poeth / rholio oer

Arwyneb: Drych 8K

Safon Deunydd

| Rhif 1 | GB | RWSIA | AISI, STM | JIS | BS | DIN | ISO |

| 1 | 1Cr18Ni9 | 12KH18H9 | 302, S30200 | SUS302 | 302S25 | X12CrNi88 | 12 |

| 2 | 0Cr18Ni9 | 08KH18H10 | 304, S30400, TP304 | SUS304 | 304S15 | X5CrNi89 | 11 |

| 3 | 00Cr19Ni10 | Z2CN18.09 | 304L S30403, TP304L | SUS304L | 304S12 | X2CrNi189 | 10 |

| 4 | 1Cr18Ni9Ti | X10CrNiTi189 | |||||

| 7 | 0-1Cr18Ni12Mo2 Ti | Z6CNDT17.12 | 320S17 | X10CrNiMoTi1810 | |||

| 8 | 00Cr17Ni14Mo2 | 03KH17H14M2 | 316Ls S31603, TP316L | SUS316L | 316S12 | X2Cr | 19,19 |

| 9 | 0Cr25Ni20 | 310S, S31008s TP310S | SUS310S | ||||

| 15 | 0Cr23Ni13 | 309S、S30908 | SUS309S | ||||

| 16 | 0Cr17Ni12Mo2N | 316Ns S31651 | SUS316N | ||||

| 17 | 00Cr17Ni13Mo2N | Z2CND7.12N | SUS316LN | X2CrNiMoN1812 | |||

| 18 | 0Cr18Ni12Mo2Cu | SUS316JI | |||||

| 19 | 00Cr18Ni14Mo2Cu2 | SUS316JIL | |||||

| 20 | 0CM9NM9N | ZCNS18.09A2 | 304 | SUS304N |

Cydran Cemegol

| Gradd | C | Cr | Ni | Mo | Arall |

| 301 | ≤0.15 | 16.0 ~ 18.0 | 6.00 ~ 8.00 | - | - |

| 301L | ≤0.030 | 16.0 ~ 18.0 | 6.00 ~ 8.00 | - | N≤0.20 |

| 304 | ≤0.08 | 18.0 ~ 20.0 | 8.00 ~ 10.50 | - | - |

| 304J1 | 0.02 ~ 0.05 | 16.5~ 17.1 | 7.5~ 7.9 | - | Cu1.9~2.2 |

| 304L | ≤0.030 | 18.0 ~ 20.0 | 9.00-13.00 | - | - |

| 304N1 | ≤0.08 | 18.0 ~ 20.0 | 7.00 ~ 10.50 | - | N0.10~ 0.25 |

| 304N2 | ≤0.08 | 18.0 ~ 20.0 | 7.50 ~ 10.50 | - | Nb≤0.15 |

| 316 | ≤0.08 | 16.0 ~ 18.0 | 10.00 ~ 14.00 | 2.00 ~ 3.00 | - |

| 316L | ≤0.03 | 16.0 ~ 18.0 | 12.00 ~ 15.00 | - | - |

| 321 | ≤0.08 | 17.0 ~ 19.0 | 9.00-13.00 | - | ti5×C% |

| 409L | ≤0.03 | 17.0 ~ 19.0 | - | - | Ti6×C% ~0.75 |

| 410L | ≤0.03 | 11.0~ 13.5 | - | - | - |

| 430 | ≤0.12 | 16.0 ~ 18.0 | - | - | - |

| 430J1L | ≤0.025 | 16.0 ~ 20.0 | - | - | Nb8 (C%+N%)~0.8 Cu0.30~0.80 |

| 436L | ≤0.025 | 16.0 ~ 19.0 | - | 0.75 ~ 1.25 | Ti, Nb, Zr8 ×(C%+N%)~0.8 |

| 410 | ≤0.15 | 11.5~ 13.5 | - | - | - |

| 420J1 | 0.16~0.25 | 12.0~ 14.0 | - | - | - |

| 420J2 | 0.26 ~ 0.4 | 12.0~ 14.0 | - | - | - |

| 2205 | 0.38 ~ 0.43 | 21~23 | 4.5~ 6.5 | 2.5~ 3.5 | - |

| 2507 | ≤0.03 | 24.0~ 26.0 | 6.00 ~ 8.00 | 3.0~5.0 | - |

Arwyneb Cyflwyno

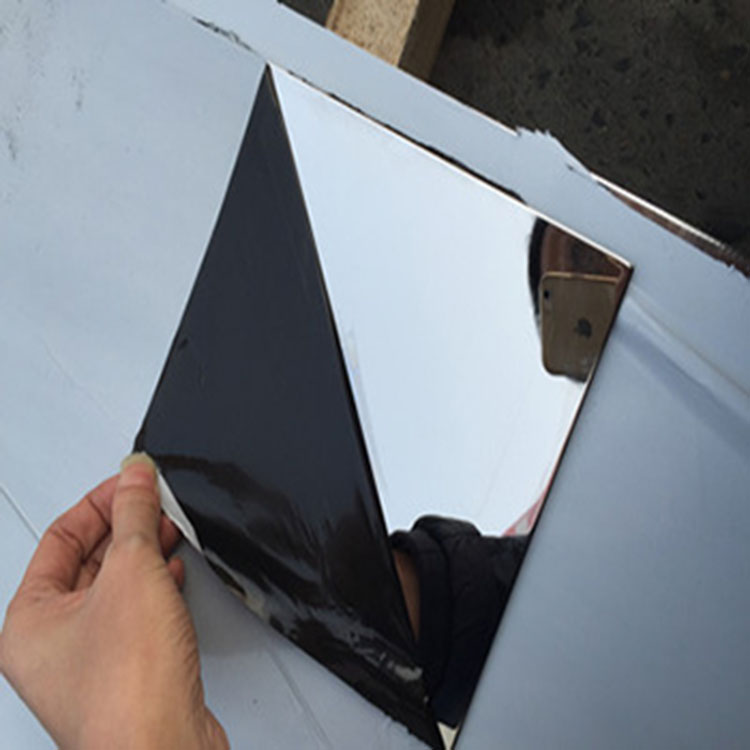

GORFFEN 8K :

Sgleinio'r plât dur di-staen gyda hylif caboli trwy sgleinio offer, fel bod disgleirdeb y plât mor glir â drych.

Eglurhad: Deunyddiau crai dur di-staen, ar ôl prosesu malu a chaboli, bydd yr wyneb yn llyfn a gyda sglein drych, plât dur di-staen,

ynoyw 2B, BA, arwyneb cyffredin, arwyneb 8K, arwyneb 8K yw'r 8k goraudalen ddur di-staengellir ei blatio lliw, fel y plât lliw dur di-staen 8k

Cais

yn cael ei ddefnyddio ar gyfer bwrdd wal neuadd, nenfwd, bwrdd car elevator, bwrdd ceir, addurno adeiladau, byrddau arwyddion ac addurniadau eraill, defnyddir bwrdd dur di-staen lliw yn gyffredinol wrth addurno'r wal ac addurniadau eraill

Sioe Cynnyrch

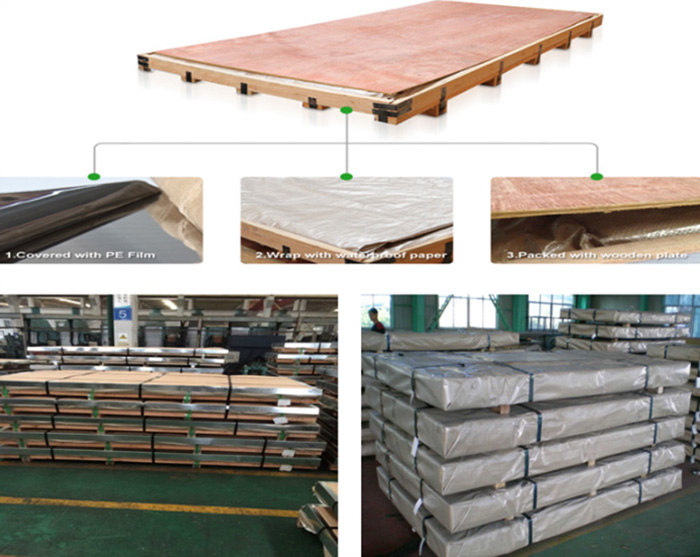

Pecyn

Anfonwch eich neges atom:

Ysgrifennwch eich neges yma a'i hanfon atom